Underwater Consultants, Surveyors and Engineers

Recent Recovery of Anchor and Chain from the Stena Nordica in Holyhead

Posted by Sandra Hazard

|

Many thanks for the successful recovery of the anchor from the sea bed and for today's support. |

|

Renewal of all certifications

Posted by Sandra Hazard

|

Renewals of all certification are in place for copy of certification click on our home page on the icons and you will see updated certificates. Please note we are now working on moving forward to achieving ISO450001 for 2021. |

Renewal of SafeContractor Certification

Posted by Sandra Hazard

|

Salvesen are very pleased to announce to past, present and future clients that we have achieved a very high standard during the assessment of our SafeContractor (Alcumus) accreditation for another year. Anyone who we have worked for knows how much we pride ourselves on delivering the best standards of Health and safety possible for all of our Clients. |

Renewal of Achilles Certification

Posted by Sandra Hazard

|

Salvesen UK Ltd are happy to share with all our clients the renewal of our Achilles Accreditation - Certificate on website another great achievement from our professional team. |

Achieved our Renewal Certifications

Posted by Sandra Hazard

|

Salvesen Uk Ltd are proud to share that we have successfully achieved our renewal certifications from Alcumus ISOQAR for ISO9001-2015 Quality & ISO14001-2015 Environment for another year. We have also achieved the SafeContractor Accreditation, see at the bottom of our home page to view all certifications. |

RSS Sir David Attenbrough

Posted by Sandra Hazard

|

Congratulations to Cammell Laird with the launch and future fitting out of RRS Sir David Attenbrough. Salvesen UK Ltd were pleased to assist by providing guard boat cover with further dive support within the Cammell Laird Wet Basin. |

|

New Accreditations

Posted by Gary Canning

|

ISO 9001-2008 - The Auditor spent a very interesting day with Salvesen Personnel being shown the full Quality system covering Health and safety , financial and operational procedures. He visited a diving operation in progress and was shown all the relevant documentation and procedures within the ISO 9001-2008 system actually in action on a live operation. Tracing the project from the first enquiry through the system to the final invoice payment. The auditor commended Salvesen UK on their Quality System and submitted a report with zero Minor and zero Major non-conformances. This is Salvesen UK 18TH successful yearly audit and the company continues to improve and produce a high level of professionalism for all their clients.

Contractor Plus - Salvesen successfully renewed their Contractor Plus Health and Safety accreditation via an on line safety audit for a further year. |

MV Thor Overhaul

Posted by Gary Canning

| Salvesen UK Dive Support vessel MV Thor was lifted out of the water this month for a complete overhaul and renewal of MCA Coding. Over £10,000.00 was spent on the vessel with full shot blasting of Exterior paint and 2 new coats of antifouling applied, new anodes throughout, along with the propeller being refurbished. Full reconditioning of it's caterpillar engine and all safety equipment was serviced, exchanged and approved. The vessel was out of the water for 6 days and placed back in the water on the 3rd of April to be mobilised immediately for up and coming project in Birkenhead docks. |

|

Emergency in Gloucester

Posted by Gary Canning

| Emergency call to Gloucester to assist in installation of new dock gates. Salvesen UK was contacted by a client whom they had completed a project for 2 years previously. Salvesen arranged all safety documents and travelled to site early the following day completed operation and returned that evening. Main client was Kier who had not used Salvesen UK in recent years and on completion made following testimonial. |

|

Posted by Carl Huston

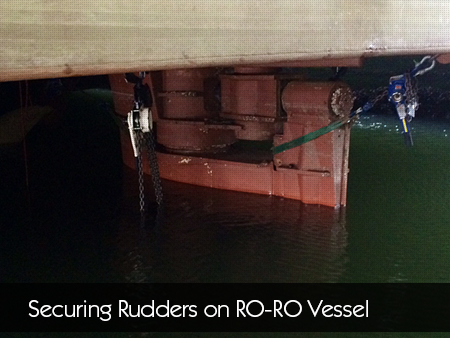

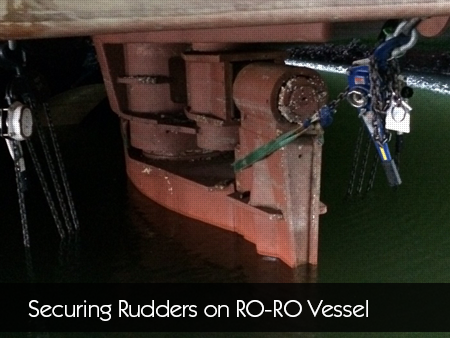

| Our diving operation was to secure the rudders on a large RO-RO vessel, to allow the replacement of the steering seal assembly.

The rudder (14T) was bodily supported under the sole plate of the “Becker” type rudder, using a 20T webbing strop attached to heavy pull lift blocks onto the hull.

Smaller pull lifts attached Forward and Aft’ to prevent any lateral movement of the rudder. This prevented any movement internally, as the removal of the steering assembly inboard gave no security of the rudder |

|